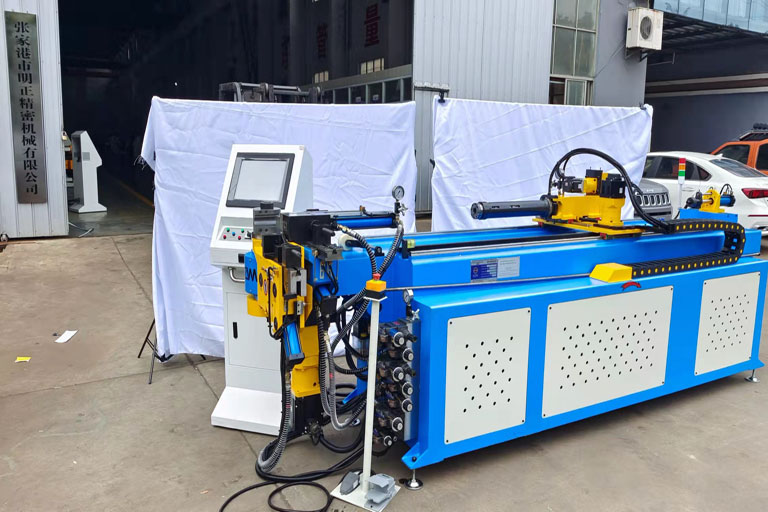

CNC Industrial Inexpensive Tubing Bender | MZ50CNC-3A-1S

CNC Industrial Inexpensive Tubing Bender

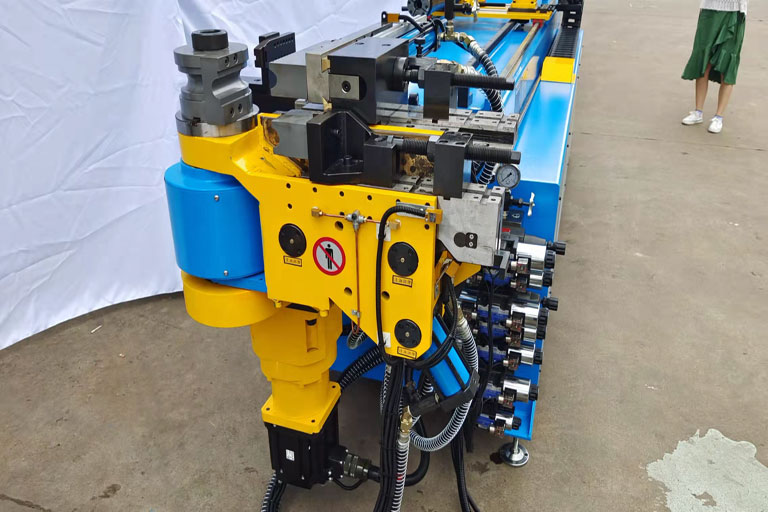

● Dual-Drive System: Combines servo and hydraulic drives for efficient, precise operation.

● Advanced Control: Centralized electrical control of bending angle, feeding accuracy, and tube rotation.

● Hydraulic System: Independent hydraulic cylinders for clamping, guiding, mandrel, and other key functions, ensuring smooth, synchronized movement.

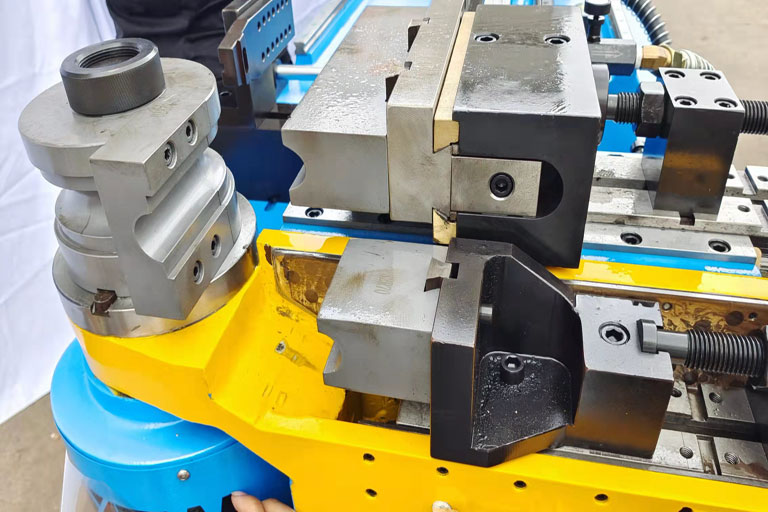

● Bending Versatility: Supports both mandrel and non-mandrel bending for different pipe types.

● Easy Operation: Offers jog and single-action modes for simple operation and maintenance.

● Wide Application: Used in shipbuilding, boilers, chemicals, and automotive manufacturing industries.

Industrial pipe bending machine with PLC or IPC that manages Feeding (Y), Rotation (B), and bending (C) in a complete automatic cycle.

Fully hydraulic movement on clamp die, pressure die, and mandrel.

Available pipe material: steel, stainless, aluminum, titanium, and brass...

Available pipe shapes: Round, Square, Rectangle, Oval, Solid Bar, and other profiles...

Equipped with a Japan Omron encoder ensures the accuracy and stability of bending.

Only use world-famous popular quality components in the production of our industrial pipe bending machine: Japan Mitsubishi Servo, Hydraulic Germany Rexroth, Electrical France Schneider, Seal ring Japan NOK, CNC Controller Siemens or Japan Mitsubishi, and so on.

Europe designs structures with higher precision and speed. keep the machine used for a long time.

The main function of the system is to control the hydraulic fluid distribution, precisely adjusting the bending angle and degree to enable efficient pipe processing.

The main function is to securely hold the pipe during bending, ensuring stability and precision, with adjustable fixtures and molds to accommodate different pipe sizes and shapes for efficient processing.

Specification

| NO. | Name | Unit | Parameters | Mark | |

| 1 | Max Processing Pipe Size | mm | Φ50×3t | Carbon steel | |

| 2 | Bending radius | mm | R180 | ||

| 3 | Max feeding length | mm | 2500 | Can be customized | |

| 4 | Feeding method | 1. Direct feeding

2. Clamping feeding |

Optional | ||

| 5 | Max bending angle | Degree | 190 | ||

| 6 | Using controller | PLC | |||

| 7 | Number of bends per fitting | 个 | 30 | ||

| 8 | Working speed | bending | Deg/sec | 80 | 8 |

| rotating | Deg/sec | 120 | |||

| feeding | Mm/sec | 800 | |||

| 9 | accuracy | feeding | mm | ±0.1 | 9 |

| rotating | Degree | ±0.1 | |||

| bending | Degree | ±0.1 | |||

| 10 | Rotating servo motor | W | 750 | Mitsubishi | |

| 11 | Feeding servo motor | W | 1500 | Mitsubishi | |

| 12 | Bending servo motor | W | 7000 | Mitsubishi | |

| 13 | Data input mode | 1、Coordinate value(X、Y、Z)

2、Working value(Y、B、C) |

Optional | ||

| 14 | Hydraulic motor horsepower | Kw | 5.5 | ||

| 15 | Maximum pressure | MPa | 14 | adjustable | |

| 16 | Hydraulic system control | solenoid directional valve | Taiwan's Seven Oceans | ||

| 17 | Fuel tank capacity | L | 180 | ||

| 18 | Machine weight | Kg | 2500 | ||

| 19 | Machine size | cm | 480×110×130 | ||

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802